Description

About the Fadal 1100 Boards

Before replacing your 1100 board:

The 1100 board is a passive power distribution board, therefore, by design there are no ICs on the board that could fail and cause a need to replace the board. All the failure components on the board are plug-able and should be replaced before replacing the entire 1100 board. The only reason to replace the 1100 board would be because of a broken or burnt trace on the board.

How it works:

The board receives a signal from the the control to actuate a Solid State Relay that outputs power (120 VAC) to a device. The relay has 4 pins: two are control pins and the other pins are the SSR output. The control pins are identified as + and -. The + pin always has 5 VDC supplied. The state of the - pin is controlled by the CNC. In the off state the - control pin is "floating" and the circuit is in the open state. To turn on the SSR, the CNC sinks the - pin to ground which completes the circuit and turns on the output. As a note, one characteristic of the SSR output is that is "leaks" voltage and without a load of approximately 20 watts, you will measure 120 VAC output regardless of the SSR control +- state.

To test the SSR control circuit, remove the SSR and measure the DC voltage at the +- control sockets of the 1100 board. Measuring 0 voltage indicates an OFF condition, +5 VDC indicates an ON condition.

We've included a Fuse List (below) to help identify which SSR drives each component.

The list reads from left to right and provides all the information for the control and output circuit on the board.

For Example, looking at the SPINDLE COOLER PUMP. The input 120 power starts at F9 fuse, feeds SSR at location K15. The output of the SSR then goes out to terminal TB2, wire location 18 and 17.

There are two types of outputs, one output such as the COOLER PUMP goes directly from the SSR to the pump. The other type is SPINDLE ON, the SSR controls a mechanical contactor labeled K3. The contactor is commonly referred to as an "Ice Cube". The Ice Cube contactor is then used to switch power (more wattage) or signal (grounding a signal).

Important Note: Solid State Relays K13, K11,K23, K24, K7, K9 will not measure or output 120 VAC when in the Emergency Stop condition. They are part of an interlock that uses the 120 VAC supply from the Estop Circuit.

Below are a few simple tests to do before replacing the board:

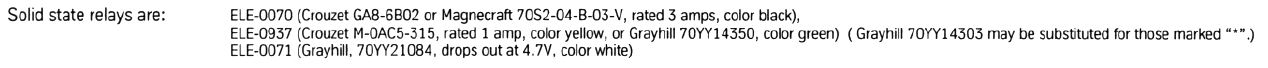

1) Verify the correct SSR is being used. Just because the wrong SSR might have worked for a while, it is important to use the correct SSR. As you'll see below one type is rated at 3 amps while another is rated at 1 amp.

2) Replace SSR and Ice Cube contactors in the problematic circuit.

3) For SSR - K13, K11,K23, K24, K7, K9, verify the CNC is not in an ESTOP Condition.

4) Remove and clean the 100 pin gold edge connector of the 1040 Mill Interface board (Slot #17). See the Cleaning discussion about control boards.

5) Verify the SSR control circuit has 5 VDC supplied to the + control socket by measuring from ground (the casting ground) to the + control socket.

6) Test the functionality of the +- control of the SSR. Measuring between the +- control sockets to verify a measurement of 0 volts for OFF and +5 volts when ON. Doing this will verify that the 1040 Mill Interface board (Slot #17) is functioning correctly.

7) For issues with the Carousel tool changer motors for Turret or TC slide IN/OUT operations: Check the two large, square capacitors labeled C1 and C2 on the 1100-2 board usually located in the back cabinet, below the main transformer. The Turret motor uses the capacitor labeled C2. The TC Slide motor uses the capacitor labeled C1. They are interchangeable so you can swap the capacitors.

8) Verify the boards are clean and not shorted by chips. The back side of the boards require board removal.

9) Inspect the board for any damaged traces.

To aid in determination if the board indeed needs replacing, we've included an electrical diagram for these boards in the Technical Document Section - Click Here to view it.

1100 Board Specifications:

Part Number - POWER DISTRIBUTION BOARDS

- PCB-1100-1B

- PCB-1100-2D, 21102

- Remanufactured

- One Year Warranty

About the 1100 Power Distribution Boards:

Every machine uses two 1100 boards for controlling various devices.

1) 1100-1 Board:

The Power Distribution and Relay PCB 1100-1 has inputs of 120VAC, 5VDC and the control signals. The control signals used by the 1100-2 board are routed to another connector and go to the 1100-2 board. The control signals from the Mill Interface (1040) activate relays when required by pulling the control line low or about zero volts. This board has the Emergency Stop relays K1 & K2, high & low range, coolant pumps, Amplifier control, M-functions and power to the pendant. Below, is for your reference.

2) 1100-2 Board:

The Power Distribution and Relay PCB 1100-2 has inputs of 120VAC, 5VDC and the control signals. The control signals from the Mill Interface (1040) and Spindle Controller (1010) activate relays when required by pulling the control line low or about zero volts. This board has the spindle forward & reverse signals, ATC controls, Drawbar, Orientation and waylube. Below is for your reference.

True Knowledge and Experience you can Trust:

Experience - Always Your Best Choice:

Having been involved in the original design and production of the Fadal CNC hardware and software, we truly understand these boards - from the component level to the requirements for properly repairing and testing all of the boards we offer.